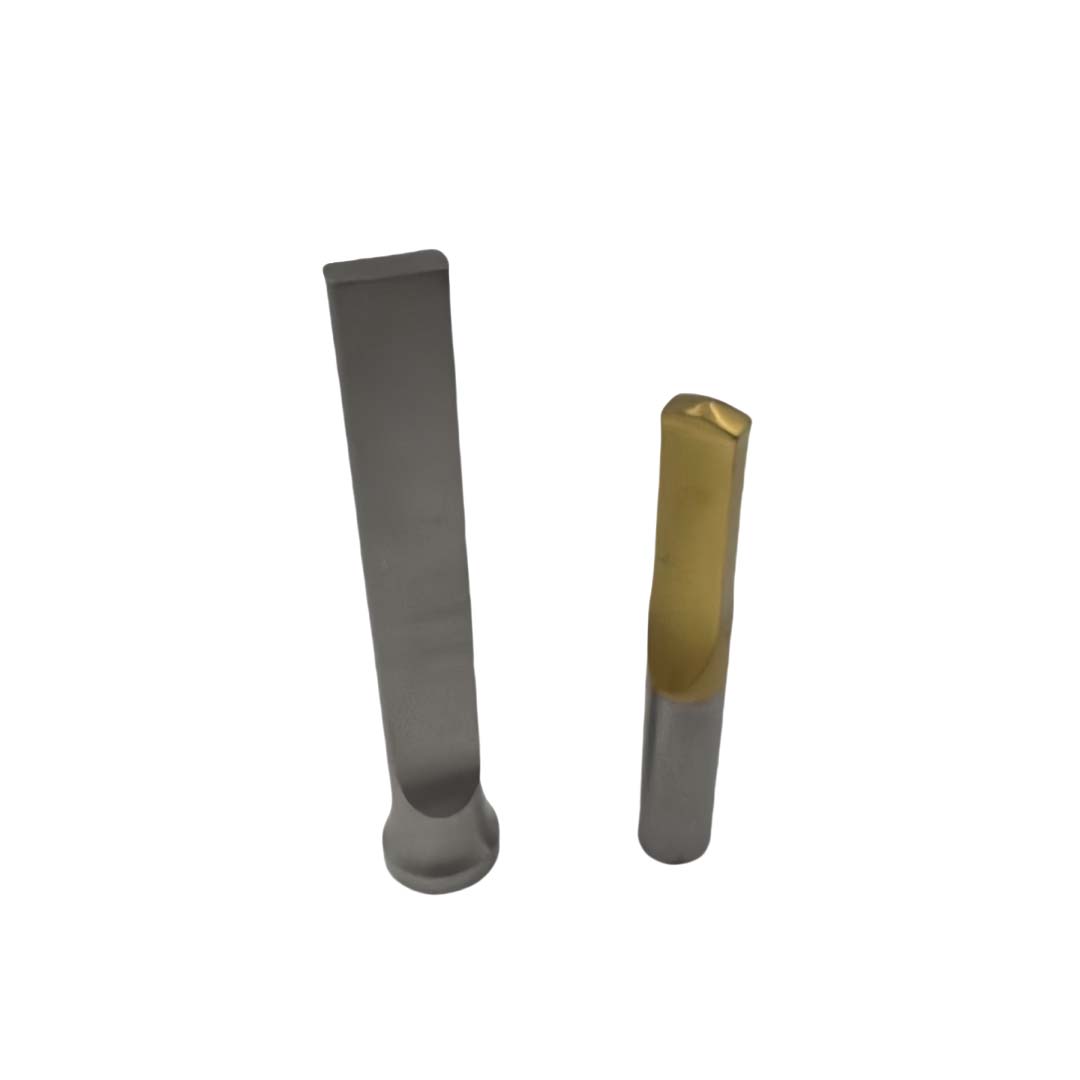

Standard vs Custom Ejector Pins: What Are They?

Ejector Pins–Ejector pins (sometimes also called top pins or top rods) are used for workpiece securing, stability, precision, etc in the mechanical processing world. Standard ejector pins are widely used and appreciated because they are cheap and flexible, while there is an increasing need for custom ejector pins according to the specifics of processing. In this article, we will discuss what the differences are between standard ejector pins and custom ejector pins and when to use either of them.

What Are Normal Ejector Pins?

Standard ejector pins, which are pre-manufactured pins offered in a variety of shapes, sizes, and materials. They are made to meet general processing needs and widely used in different industries for their price and easy availability. Here are some key features of standard ejector pins:

Standardized Specs: Offered in designated lengths, diameters and materials, including steel or carbide.

Applications: Multiple Industries, From Basic Machining To Injection Molding.

More Affordable: Opting for a smaller, more affordable designs than bespoke solutions.

Restrictions on Customization: You can only use designs and materials that have been preset.

What Are Custom Ejector Pins?

Custom ejector pins are designed to meet the specific needs of a particular application, and are manufactured for a particular customer. In contrast to standard pins, custom ejector pins can be designed to meet unique challenges, including complex geometries, extreme operating conditions, or special performance characteristics. Custom ejector pins are best known for:

Specific-to-Needs Design: Satisfies the precise size, form, and material required for the use case.

Improved Performance: Built for high precision, high load, or extreme environmental conditions.

Long Life Span: Mainly constructed with high quality materials well optimized for durability and wear resistance

Higher Cost: Typically involves more investment over customized and tailored production processes.

Difference Between Standard and Custom Ejector Pin

Data Set on Overall Costs and Affordability Customisable to the specific needs.” Material ChoicesStandard materials. May use esoteric or exotic materials. PerformanceYou can receive general most applications. Fine-tuned for super-high accuracy, massive weight, or harsh conditions. CostLower initial cost. Costlier initial investment due to being custom designed. Lead TimeLess time to produce. Customized so lead time is longer. Best for standard or simple applications. Suitable for advanced or highly specific applications.

When to Use Standard Ejector Pins?

Standard ejector pins are a great fit for:

General Processing Needs: Standard applications, including simple machining or basic injection molding.

Budget Constraints: When cost is a key factor and thought is not needed.

Fast Turn Around: For third party solutions that have good shelf life on projects with short timelines.

Why Do You Need Custom Ejector Pins?

The custom ejector pins are the chiefly opted ones for:

Complex Applications: When the processing environment requires high precision, heavy loads or even extreme conditions.

Specialized Requirements: Unique geometries, materials or surface treatments not found in standard options

Cost-Efficiency: Where a more expensive but durable solution is cheaper in the long term.

Applications with custom designs to accommodate machinery or workpiece configurations.

Selecting the Appropriate Ejector Pin

Evaluate Your Processing Requirements: Determine your applications complexity, level of accuracy, and deployment environment.

Budget Considerations: Compare the up-front and long-term costs of standard vs. custom options

Seek Guidance from a Trusted Manufacturer: Engage an expert ejector pin manufacturer to help you find the right solution for your requirements.

Get Samples or Quotes: Most manufacturers would provide you with samples or detailed quotes to help you make decisions.

Conclusion

So, knowing what the standard ejector pins are vs the custom ejector pins helps you to choose the right type based on your mechanical processing requirements. Standard ones are versatile and affordable but custom ones provide the precision, durability and performance needed for complex or specialized applications. Identifying your unique needs and price range allows you to determine which type of ejector pin is right for you to make sure you have the best processing outcomes possible.

Get in touch if you need a professional ejector pin maker providing OEM and custom-made solutions. We will help you match the right ejector pin to your application with years of experience and a dedication to quality.

youtube:https://youtube.com/shorts/A0iqD7RjMcI

Language

Language