With today's fast-paced manufacturing environment, we all know that time is money and accuracy is king. Whether you’re manufacturers of automotive parts, electronic components, or fasteners, every millisecond of saved production time and every percentage point of improved accuracy is not to be dismissed lightly as it could greatly impact your bottom line. Enter the Multi-Station Punch Pin – the game-changer that has revolutionized this aspect of manufacturing processes, enhancing speed and precision.

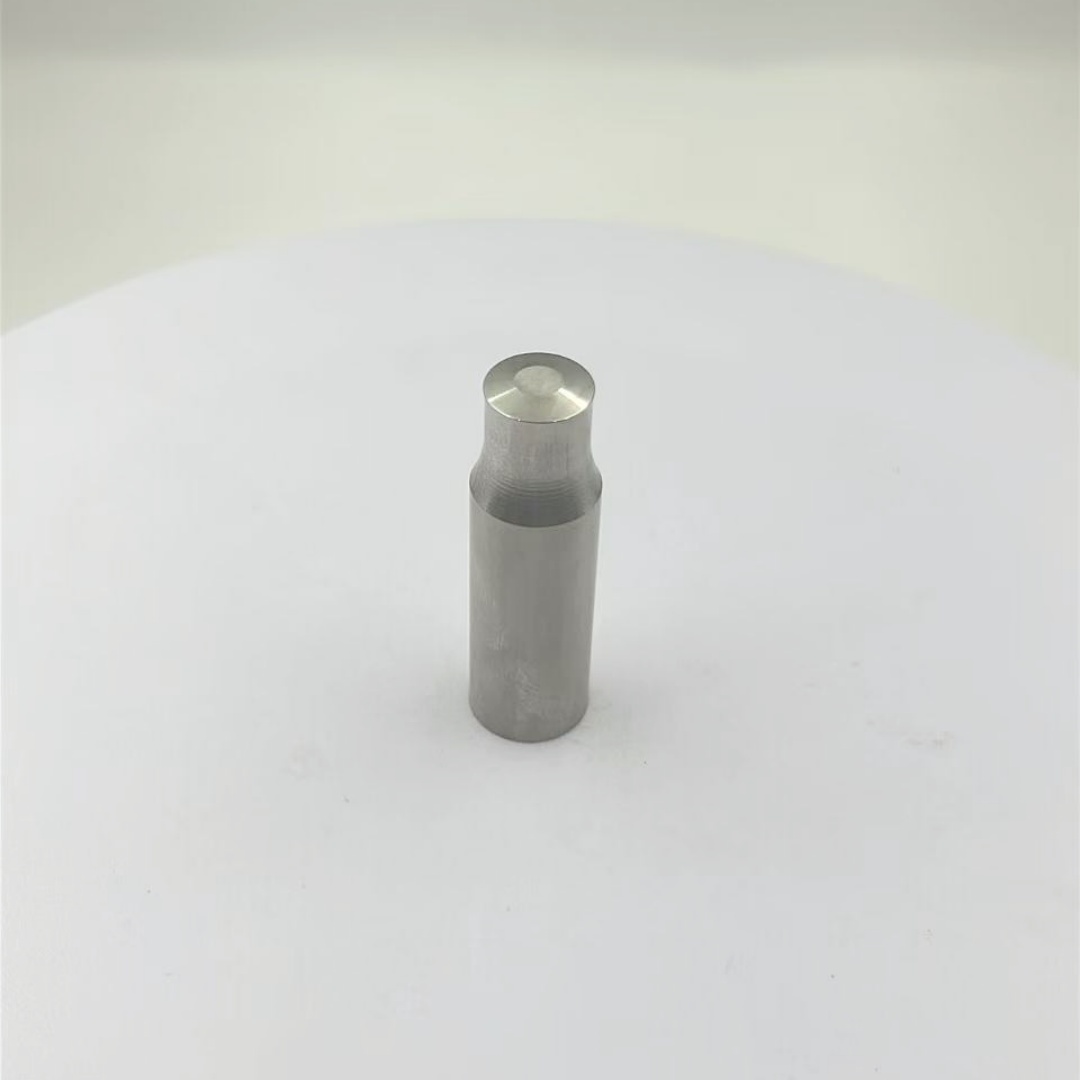

What are Multi-Station Punch Pins?

The Multi-Station Punch Pins are an advanced solution for enhancing the punching operation, particularly in the high-volume manufacturing process. The above pins are designed to support multiple punching at once, in a single cycle to achieve several operational. This is a huge leap from standard punching, as each punch requires its own tooling and process.

A Multi-Station Punch Pin combines multiple workstations, each containing its own punch and die, into a single tool. Multiple punches, holes, or cuts can be achieved at one time, which saves time and boosts productivity.

You Are Relying on Multi-Station Punch Pins for Your Manufacturing Process

Faster Speed, Shorter Cycle.

The most noticeable advantage of Multi-Station Punch Pins is the significant decrease in cycle times . Multi-Station Punch Pins have multiple operations that can be performed per press which in turn decreases production times.

One of the most popularly harnessed benefits of using advanced pin designs in metallurgy is that a Multi-Station Punch Pin punches multiple holes in a part in single cycles even at multiple stations of a press. This results in shorter production times and increased output/throughput, allowing your shop to produce more parts in less time.

Increased Accuracy and Consistency

In production, minor variances in dimensions of a part can result in defective products, scrap, and expensive reworks. You are … know about Multi-Station Punch Pin: how it ensures perfection with every pin. Given that all the punching is done simultaneously, while using one single setup, there’s less chance of error in comparison with classical, sequential punching methods. As a result, it is a higher quality product with fewer flaws.

Cost-Effective Production

Multi Station Punch Pins help lower manufacturing costs by increasing both speed and accuracy. Multi-tasking reduces the need for multiple machines, operators and setups, which is even better. Also, independence from 3rd parties will allow you to shorten cycle times, and in doing so significantly reduce energy consumption, labor costs and raw material waste. This can lead to significant savings over time for your bottom line.

Improved Flexibility and Versatility

Multi-Station Punch Pins — one of the most flexible pin types on the market; able to perform a great range of punching functions. They can be designed to position punches in numerous shapes, sizes, and configurations, making them useful in a wide range of industries. From punching holes and forming shapes to embossing designs, these pins provide the versatility needed for various manufacturing processes.

Multi-Station Punch Pins are also modular. Manufacturers can replace and exchange the various interchangeable parts and adapt the tool to the right product specification or production run. This adaptability allows manufacturers to keep pace with a marketplace that increasingly requires speed and responsiveness.

The uses of multi-station punch pins

The uses of the Multi-Station Punch Pins are endless. These are just a few of the industries that can take advantage of these high-performance tools:

Automotive Industry: Use it to punch holes in sheet metal, form shapes for automotive components, or even create complex designs in car body panels.

Electronics Manufacturing: Punching holes in PCBs, making connectors, or making boxes for electronic devices.

Fastener Production: Directly manufacture repair or fastener, screws, bolts, nuts, and washers with perfect holes and thread all in one go.

Metal Fabrication: Various industrial equipment parts, from punching, cutting to metal embossing.

Multi-Station Punch Pins in Your Manufacturing Line

You will need to thoroughly plan for this implementation, as well as integrating any aspects of the Multi-Station Punch Pins into features you may already have in place. Here are steps to consider when deploying these tools:

Step 1: Consider Your Existing Manufacturing Requirements: Identify, where in your production line can you improve speed and precision. TASKS: If you are repeatedly punching or performing a complex multi-step operation, then take some time to identity those tasks.

Select the Proper, Multi-Station Punch Pin: Depending on your production runs' complexity, and the materials, you work with, you have to choose a Multi-Station Punch Pin that is best suited for your needs. Make sure it integrates with your current equipment and processes.

Add it to Staff Training: Although Multi-Station Punch Pins are much more efficiency-oriented, they may require your operators to undergo training during their production line installation. Make them aware of how to get the best usage out of the tool, and how to keep it running.

If the newly added tool is not meeting the expectations, closely monitor its performance after implementation. Monitor progress in speed of production, accuracy, and cost savings. With time, this will help you refine your processes even more.

Conclusion

Multi-Station Punch Pins can help manufacturers to do just that — speeding up production while improving accuracy and productivity. This allows for parts to be produced quicker while also reducing cycle times, meaning less time each step in the punching process takes, resulting in a higher standard of quality. In turn, this translates into cost savings, enhanced competitiveness, and a more agile manufacturing environment.

With speed and precision being the mantra in a fast-paced world, Multi-Station Punch Pins are way to go if you want to beat the competition and keep up with the demands of the ever-evolving industries. If you are looking to elevate your manufacturing process and skyrocket the productivity of your production line, then want to implement Multi-Station Punch Pins in your production line. The advantages are obvious, and the outcomes tell their own story.

YOUTUBE:https://youtube.com/shorts/J97q_3Mcnj8

Language

Language