Welcome to Hengzan Xin Hardware Machinery Co., Ltd

Production material: high-speed steel, powder high-speed steel, tungsten steel/carbide punch , etc.

Torx punch is a cold heading die accessory, mainly used to produce plum-shaped tools and fasteners, such as Torx wrenches and internal Torx screws. It is an important cold heading die accessory. The material of Torx punch is usually high-speed steel or powder high-speed steel, which can be coated with a surface treatment to improve the service life. The plum-shaped hole of Torx punch can be formed in one time, which improves the work efficiency, and the products produced by the same punch have small shape deviation and high precision. Torx punch is a punch with a Torx-shaped end, which is used for stamping.

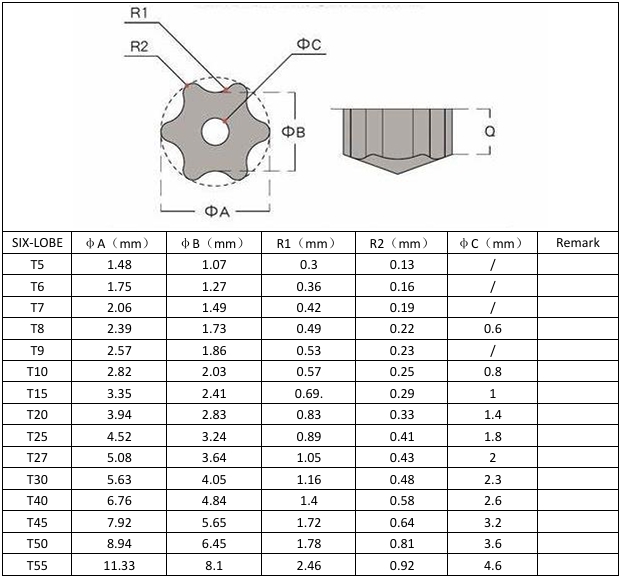

Dimensions:

Length: Customizable, based on the mold and process requirements.

Diameter: Varies depending on the punch size; typically ranging from a few millimeters up to several centimeters.

Material: High-quality tool steel, carbide, or other specialized metals for durability and strength.

Hardness: Generally hardened to 55-60 HRC, depending on material and application.

Tolerance: Precision manufacturing with a typical tolerance range of ±0.01mm.